Local brickworks, including in rural locations, were once extremely common as were cement works, pottery works and quarries of various extractables. Many such brickworks were built by local squires or businessmen to facilitate building projects in the locality and in some cases simply to create employment, but all depended upon a local source of raw materials. Warboys was one such suitable location. Warboys sits on Corallian Rock and the brickworks sat on the edge thereof and adjacent to clay beds. From the surface down is a layer of Ampthill Clay, a layer of Elsworth Rock and then a deep layer of Upper Oxford Clay. It was from the latter which clay was extracted for the brickworks. The end product was the Warboys White. White bricks, which are actually a pale creamish-yellow colour, were and still are a common sight in eastern England and elsewhere. Perhaps the best known White in the area is the Burwell White.

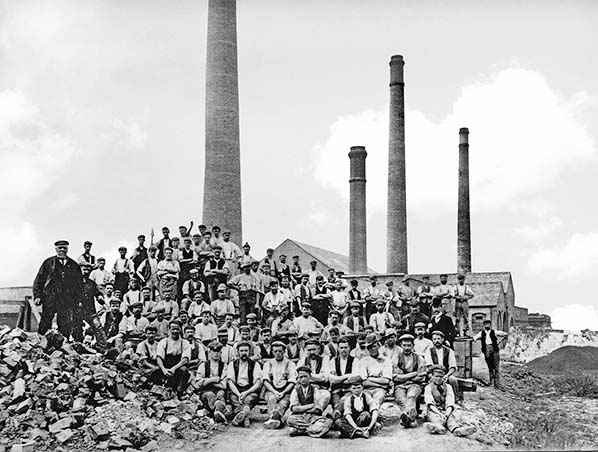

This group photograph of Warboys was taken around the time that the two Hoffmann kilns were installed, in 1906, but before the original chimney was demolished. Of the three chimney tops visible, all three are smoke-stained so the Hoffmann kilns must have been in use when the photograph was taken. We can therefore take the date as being around 1908 - 1910. The gentleman on the left may have been Mr Fuller, at this time the site owner. Of note is the apparent youthfulness of some of the group members; the three sitting at the front, for example, were probably only 14 or 15 years old. In 1910 illiteracy was still widespread and especially among rural folk who knew little about life other than earning a meagre living by working on the land. Thus it was that the emphasis was on children, boys in particular, to go out and earn a wage as soon as possible and it did not matter if the work was hard, dirty or in any way dangerous.

This group photograph of Warboys was taken around the time that the two Hoffmann kilns were installed, in 1906, but before the original chimney was demolished. Of the three chimney tops visible, all three are smoke-stained so the Hoffmann kilns must have been in use when the photograph was taken. We can therefore take the date as being around 1908 - 1910. The gentleman on the left may have been Mr Fuller, at this time the site owner. Of note is the apparent youthfulness of some of the group members; the three sitting at the front, for example, were probably only 14 or 15 years old. In 1910 illiteracy was still widespread and especially among rural folk who knew little about life other than earning a meagre living by working on the land. Thus it was that the emphasis was on children, boys in particular, to go out and earn a wage as soon as possible and it did not matter if the work was hard, dirty or in any way dangerous.

Warboys brickworks originated in 1891 when a Mr Alfred Fuller purchased the land. The works opened in 1893, producing bricks by the once traditional hand method and wages were £1 per week for the 50-or-so employees. By 1896 the works had been enlarged and the first pressed bricks produced; pressed bricks were harder and guarantee uniformity in bulk production. The siting of the brickworks did, of cours,e benefit from the pre-existing railway line. The siding serving the brickworks is something of a mystery as surviving railway company records are strangely silent on the matter. The siding is known to have been in existence by 1901 so we can safely assume it was installed when the brickworks was built. Ingoing traffic would have comprised mainly fuel: coal, coke and oil, with finished products outgoing. However, as was so often the case, with the advent of reliable road motor transport outgoing products, other than large bulk consignments, were switched to this means of transport and this is known to have been the case at Warboys by 1930.

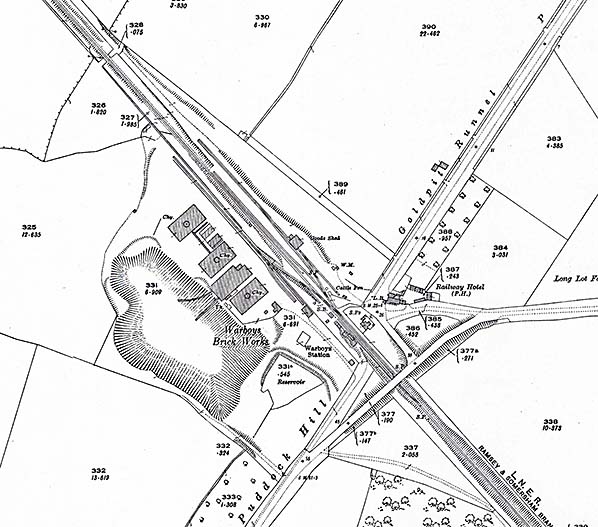

A 1926 OS 1:2500 map of Warboys railway station and brickworks area. Warboys village is some distance away off the map to the right. Somersham is to bottom right and Ramsey to top left. The brickworks had at this time been open for less than thirty years and it is interesting to compare the then size of the clay pit to its vastly expanded size in later views. On the railway most features are marked; signals (SP); signal box (SB); weighing machine (WM); cattle pen; goods shed. Other initials represent letter box (LB) and a tank (Tk). The name 'Goldpit Runnel' may arouse the curiosity of those not familiar with the region. A Runnel is a stream or ditch while the origin of 'Goldpit' in this context is something of a mystery although it has been suggested it refers to Marigold, a type of flowering plant. Certainly there are no gold mines in the Warboys area! Click here to see a larger version

A 1926 OS 1:2500 map of Warboys railway station and brickworks area. Warboys village is some distance away off the map to the right. Somersham is to bottom right and Ramsey to top left. The brickworks had at this time been open for less than thirty years and it is interesting to compare the then size of the clay pit to its vastly expanded size in later views. On the railway most features are marked; signals (SP); signal box (SB); weighing machine (WM); cattle pen; goods shed. Other initials represent letter box (LB) and a tank (Tk). The name 'Goldpit Runnel' may arouse the curiosity of those not familiar with the region. A Runnel is a stream or ditch while the origin of 'Goldpit' in this context is something of a mystery although it has been suggested it refers to Marigold, a type of flowering plant. Certainly there are no gold mines in the Warboys area! Click here to see a larger version

During 1898-99 the works was further extended and three Hoffman kilns were provided in 1906. In 1917 an engine and generator set was installed; the engine was supplied by Messrs Belliss & Morcom, Birmingham, and may have been an internal combustion (IC) unit but this particular detail is unclear. The firm certainly supplied IC generator sets as they had done so during WW1 although they did not manufacture their own engines until 1919. Belliss & Morcom are still with us today, based in Redditch. The generator was supplied by Messrs Warren Beatty & Co. Ltd. (nothing to do with Hollywood!), London, and could output 250kWh, supplying much of the works' electricity requirements. This generator set remained in situ until the works closed but had not seen regular use for some considerable time although it was run at monthly intervals to keep it in working order. The generator appears to have been of Belgian manufacture.

The year 1920 saw the creation of the Warboys Brick Company but 1923 saw takeover by Forder & Sons, a company well known in railway circles for Forders Sidings on the Bedford - Bletchley line. Sometime shortly afterwards the London Brick Company gained a presence at Warboys and this appears to have been some sort of joint arrangement with Forder. Due to the Second World War the works closed in 1942 but the precise reason is unclear. It may have been connected with the numerous aerodromes in the area, which included RAF Warboys, for which tall, belching chimneys would have been an unwelcome neighbour and could have acted as location markers for the Luftwaffe. The brickworks had, however, taken a direct hit from a bomb during 1941.

Production recommenced in 1946 and soon afterwards hollow clay bricks were produced. Extruded bricks had been in production but this had ceased, presumably when the hollow clay bricks entered production. Other products included flooring blocks and piping for drainage etc. In 1955 an oil-fired tunnel kiln was installed and was to see the end of the familiar tall chimneys, with the Hoffman kilns being demolished in 1966. The tunnel kiln was 241ft long and could contain 40 narrow gauge wagons. The process took 38 hours and weekly oil consumption was 3,500 gallons.

Production of extruded bricks recommenced in 1983 but the following year Hanson Trust took over and the works closed down rather suddenly in August of the same year. Thus Warboys went the same way as countless other smaller brickworks dotted around the country. Hanson Trust would have looked at the economics of smaller brickworks and decided to concentrate production at larger establishments with better transport connections. It was said at the time that Warboys had the highest production costs of any of the company's brickworks. Also, the disastrous Callaghan government and then the slowdown in construction projects which began under the Thatcher government probably played their part. It was all a far cry from the boom years following the Second World War and indeed, as early as 1930 Warboys was producing 300,000 bricks per week with much of this output going to Cambridge where, as in other locations, new housing was springing up rapidly

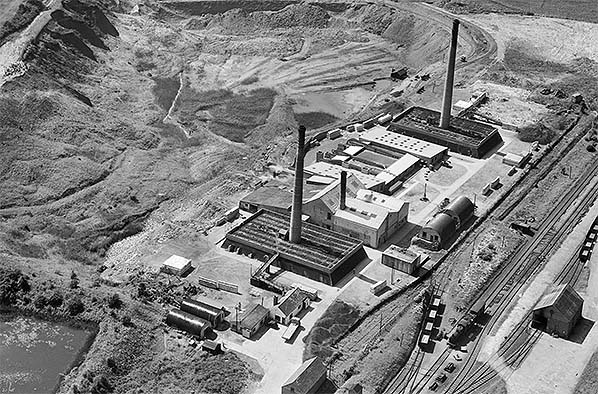

A view over Warboys brickworks looking west in June 1953. The two rectangular structures with tall chimneys are Hoffmann kilns. If the name sounds German, it is; the kiln was designed and patented by Friedrich Hoffmann in 1858. The Hoffmann kilns at Warboys were superseded by an oil-fired tunnel kiln in 1955 and the structures demolished in 1966. A number of Nissen huts can be seen. These originated during WWI but are more familiar from WWII aerodromes. It is quite possible that those seen here were purchased as military surplus after WWII. At bottom left part of the reservoir can be seen and dominating the scene above it is the enormous clay pit. The small building at the bottom of the pit was the powerhouse for a conveyor which took extracted clay to the upper level for loading into narrow gauge skip wagons. Around the perimeter of the pit and disappearing behind the building adjacent to the nearest kiln can be seen part of the narrow gauge system. To the right of the farthest chimney one of the Simplex diesel locomotives can just be seen. Also just discernable are a couple of London Brick Co lorries; one at bottom centre and another to the left of the farthest kiln. Warboys railway station is largely out of view at the bottom of the picture but the goods shed and part of the yard can be seen bottom right. Clearly visible is the siding serving the brickworks, with four wagons stabled on the connecting spur. It would appear that the loading dock was the area adjacent to the points, just below the two end-on Nissen huts. The siding divides into two at the bottom of the picture and appearances suggest loading was once undertaken along a rather longer length of the platform. The siding extends to buffers just off the picture at top right. If both sidings towards the bottom of the picture were used, one for holding loaded wagons, it would appear capacity was 14 or 15 wagons. In this view the siding appears disused although a 1961 photograph shows the connection, at least, to be apparently well used. Standing on the running line with a brake van is what appears to be a Class J17 0-6-0. To the left of the brake van are two men, probably the locomotive crew having a little break from the footplate before returning to Somersham. Click here to see a larger version.

A view over Warboys brickworks looking west in June 1953. The two rectangular structures with tall chimneys are Hoffmann kilns. If the name sounds German, it is; the kiln was designed and patented by Friedrich Hoffmann in 1858. The Hoffmann kilns at Warboys were superseded by an oil-fired tunnel kiln in 1955 and the structures demolished in 1966. A number of Nissen huts can be seen. These originated during WWI but are more familiar from WWII aerodromes. It is quite possible that those seen here were purchased as military surplus after WWII. At bottom left part of the reservoir can be seen and dominating the scene above it is the enormous clay pit. The small building at the bottom of the pit was the powerhouse for a conveyor which took extracted clay to the upper level for loading into narrow gauge skip wagons. Around the perimeter of the pit and disappearing behind the building adjacent to the nearest kiln can be seen part of the narrow gauge system. To the right of the farthest chimney one of the Simplex diesel locomotives can just be seen. Also just discernable are a couple of London Brick Co lorries; one at bottom centre and another to the left of the farthest kiln. Warboys railway station is largely out of view at the bottom of the picture but the goods shed and part of the yard can be seen bottom right. Clearly visible is the siding serving the brickworks, with four wagons stabled on the connecting spur. It would appear that the loading dock was the area adjacent to the points, just below the two end-on Nissen huts. The siding divides into two at the bottom of the picture and appearances suggest loading was once undertaken along a rather longer length of the platform. The siding extends to buffers just off the picture at top right. If both sidings towards the bottom of the picture were used, one for holding loaded wagons, it would appear capacity was 14 or 15 wagons. In this view the siding appears disused although a 1961 photograph shows the connection, at least, to be apparently well used. Standing on the running line with a brake van is what appears to be a Class J17 0-6-0. To the left of the brake van are two men, probably the locomotive crew having a little break from the footplate before returning to Somersham. Click here to see a larger version.

Reproduced with the kind permission of Simmons Aerofilms Ltd

Meanwhile, over on the clay pit side, a Ruston Bucyrus 30-RB electric dragline had been purchased in 1966 at a cost of £13,179. In 2016 prices this equates to approximately £172,000. What was used prior to this is not known but it is known that extraction was by hand until at least 1930. An interesting event occurred in 1975 when the fossilised remains of an Ichthyosaur were discovered in the clay pits. This was a prehistoric dolphin-like animal which it is thought to have became extinct 90 million years ago. Among numerous other fossils, another Ichthyosaur was discovered at the site in 1994, just prior to the site becoming landfill, and is a reminder that this part of eastern England was once under water.

The pits were served by a narrow gauge (1ft 11½in) railway system which transported clay to the works. Around the time of closure there were two Simplex (Motor Rail & Tramcar Co, Bedford) diesel locomotives; MR8936 of 1944 and MR22045 of 1959 of which the latter has survived into preservation. Details of other locomotives at Warboys over the years are not known. Simplex locomotives are simple, yet robust and reliable, and had their origins in the First World War when countless (petrol-engined) examples were produced for the military and they served with distinction on the supply lines in France. Their shortcoming, having got them started, was that they were uncomfortable to drive mainly because, even on standard gauge examples, the driver sat sideways and many a cricked neck was the result.

A Ruston Bucyrus, believed RB-30, dragline working at Warboys clay pit on 24 April 1978. The machine appears to be removing the upper layers in order to reach the clay beneath. The photographer has confirmed the date and location but the only record apparently available states Warboys acquired a new electric dragline in 1966 although the machine seen here dates from 1956. Certainly as late as 1953 excavation was manual with clay being taken by conveyor for loading into skip wagons. Possible explanations are manual excavation until 1956, or soon after, when the machine seen here appeared and the record stating 1966 is an error. Relatively slow and expensive in terms of manpower, manual extraction as late as 1966 would seem unlikely. In the background sits one of the Simplex 1ft 11½in gauge diesel locomotives, this one being w/n 8936 of 1944. The year of manufacture suggests the locomotive may have originated with the War Department. In this dimple, robust and reliable locomotive, on the right is the driving cab (many such locomotives were cabless) in which the driver sat sideways. Treatment for cricked necks was not an accessory offered by Simplex. Ahead of the cab and beneath a cowl was the engine. Engines varied according to customers’ requirements and were from a number of manufacturers. Power was typically in the 20 - 40hp range with transmission being a 2-speed constant mesh gearbox with reverse and roller-chain final drive. Ahead of the engine and very conspicuous was the cooling radiator. Functionality and little thought given to aesthetics were among the reasons why Simplex locomotives were so successful. They are still available today as are spare parts, for the rights were acquired by Alan Keef Ltd of Ross-on-Wye. With the locomotive is a rake of the ubiquitous side-tipping skip wagons which were produced in their thousands and could once been seen anywhere from mines to agricultural systems worldwide.

A Ruston Bucyrus, believed RB-30, dragline working at Warboys clay pit on 24 April 1978. The machine appears to be removing the upper layers in order to reach the clay beneath. The photographer has confirmed the date and location but the only record apparently available states Warboys acquired a new electric dragline in 1966 although the machine seen here dates from 1956. Certainly as late as 1953 excavation was manual with clay being taken by conveyor for loading into skip wagons. Possible explanations are manual excavation until 1956, or soon after, when the machine seen here appeared and the record stating 1966 is an error. Relatively slow and expensive in terms of manpower, manual extraction as late as 1966 would seem unlikely. In the background sits one of the Simplex 1ft 11½in gauge diesel locomotives, this one being w/n 8936 of 1944. The year of manufacture suggests the locomotive may have originated with the War Department. In this dimple, robust and reliable locomotive, on the right is the driving cab (many such locomotives were cabless) in which the driver sat sideways. Treatment for cricked necks was not an accessory offered by Simplex. Ahead of the cab and beneath a cowl was the engine. Engines varied according to customers’ requirements and were from a number of manufacturers. Power was typically in the 20 - 40hp range with transmission being a 2-speed constant mesh gearbox with reverse and roller-chain final drive. Ahead of the engine and very conspicuous was the cooling radiator. Functionality and little thought given to aesthetics were among the reasons why Simplex locomotives were so successful. They are still available today as are spare parts, for the rights were acquired by Alan Keef Ltd of Ross-on-Wye. With the locomotive is a rake of the ubiquitous side-tipping skip wagons which were produced in their thousands and could once been seen anywhere from mines to agricultural systems worldwide.

Photo by Kevin Lane from his Flickr Photostream

Much of the narrow gauge system at Warboys survived closure and in 1985 some 600yd of track was obtained for future use on the then fledgling Lynton & Barnstaple Railway project, it being removed from the site during 1986. The site is now used for landfill, with the first consignment of rubbish arriving in 1996.

Sources:

Home Page

Home Page

Home Page

Home Page